1. Imizobo yocango kunye nefestile

Okokuqala, nceda uhlolisise ngenyameko inkqubo yemizobo, misela uhlobo kunye nobungakanani beewindows ezifunekayo ngokungqinelana neemfuno zesitayile sokuzoba, kwaye ugqibe

Yenziwe kwaye yalungiswa-ubude, kwaye yenziwa ngohlobo olufanayo kunye neentlobo ezahlukeneyo zefestile ukuphucula inqanaba lokusetyenziswa kunye nenqanaba lemveliso.

2. Inkqubo yokhuseleko

Abasebenzi kufuneka banxibe ngokucocekileyo, banxibe iimveliso zeinshurensi yabasebenzi ngokweemfuno zomsebenzi, kwaye bagxile ekuthinteleni iingozi eziyingozi. I-Pyrotechnics ayivumelekanga ngokungqongqo kumasifundisane kwaye bonke abasebenzi abavunyelwe ukutshaya.

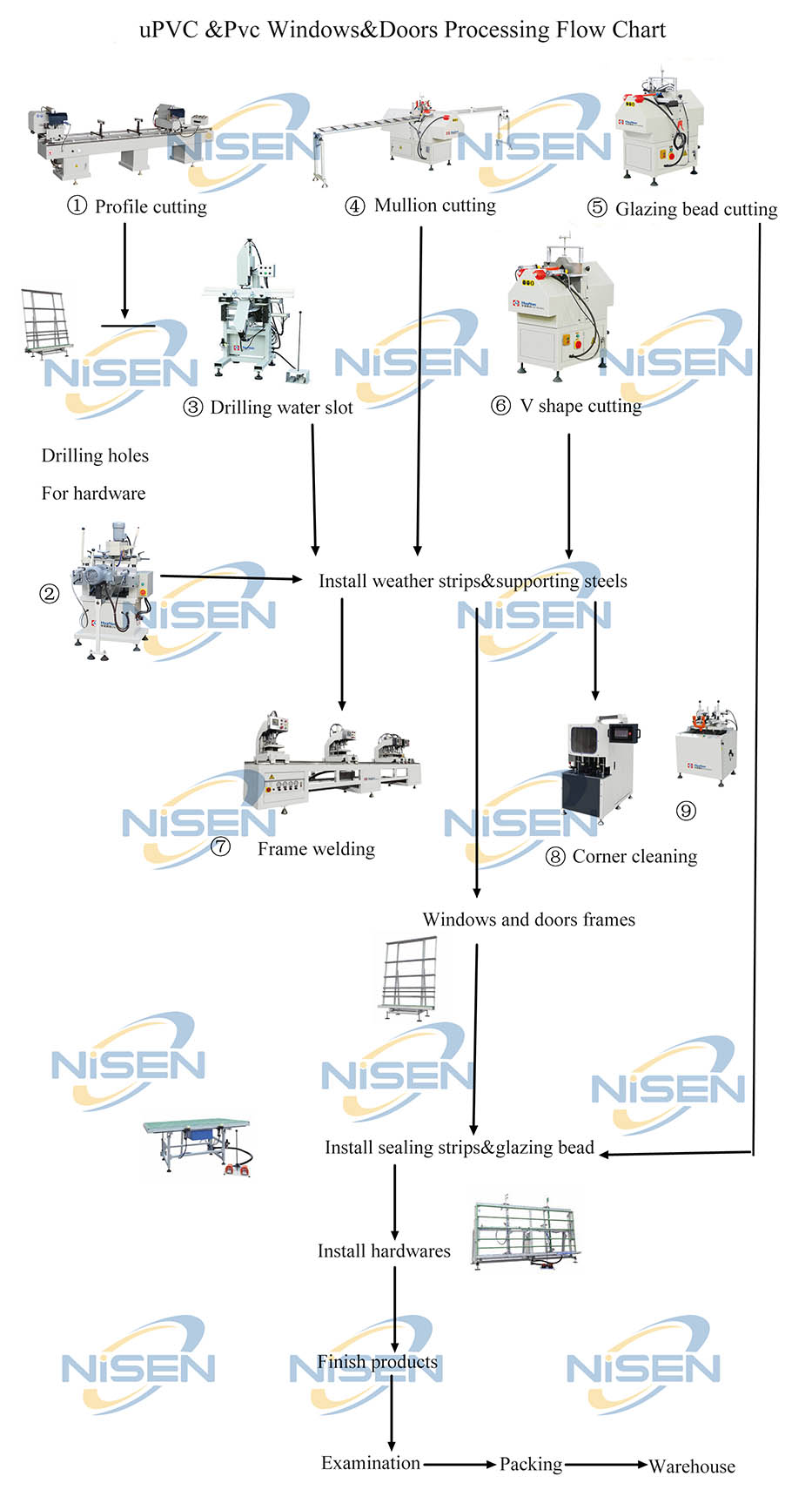

3. Ukusika iprofayili, ukugaya imingxunya yokuhambisa amanzi, imingxunya yesitshixo

A.Iprofayile ephambili yokufaka blank ngokubanzi yamkela i-miter ephindwe kabini. Shiya i-2.5mm ~ 3mm kwisiphelo ngasinye semathiriyeli njengomda, nangaphantsi kwe-welding. Ukunyamezelana kwezinto kufuneka kulawulwe ngaphakathi kwe-1mm, kwaye ukunyamezelana kwe-engile kufuneka kulawulwe ngaphakathi kwe-0.5 degrees.

B.Iprofayile yesakhelo kufuneka inyanzelwe ngemingxunya yokuhambisa amanzi, kwaye uhlobo lwe fan kufuneka ngokubanzi lusongwe ngemingxunya yokuhambisa amanzi kunye nemingxunya yoxinzelelo lomoya. Ubukhulu bomngxunya wokudonsa kufuneka ube yi-5mm, ubude be-30mm, umngxunya wokuhambisa amanzi akufuneki ubekwe kumngxunya ongene ngentsimbi, kwaye awunakungena ngaphakathi kumngxunya wentsimbi.

C. Ukuba ufuna ukufaka iactuator kunye nocango, kufuneka usile umngxunya ongundoqo

4. Indibano yentsimbi eqinisiweyo

Xa ubungakanani bomnyango kunye nolwakhiwo lwefestile bungaphezulu okanye bulingana nobude obuchaziweyo, umngxunya wangaphakathi kufuneka ube ngumgubo wentsimbi. Ukongeza, indibano yezixhobo zokusebenza Ukufakwa kwentsimbi kufuneka kongezwe kumalungu eminyango edityanisiweyo kunye neefestile kunye nokudibanisa kweengcango kunye neefestile ezidibeneyo. Kwaye uyilungise. Icandelo lesinyithi kwicandelo eliphethe uxinzelelo lwamalungu amile okwe umnqamlezo kunye ne-T kufuneka xa ipleyiti edibeneyo iphakanyisiwe nje emva kokuba icandelo liyanyibilika. Faka intsimbi ye-butt ekuqaleni kwaye uyilungise emva kokuwelda.

Izinto zokubopha zelinen yentsimbi aziyi kuba ngaphantsi kwe-3, isithuba asiyi kuba sikhulu kune-300mm, kwaye umgama ukusuka esiphelweni secandelo lesinyithi awuyi kuba mkhulu kune-100mm. Makungabikho ngaphantsi kwemingxuma emi-3 yokufaka icala elinye (ukulungisa iziqwenga) kwefestile yonke, isithuba asifanele ukuba sikhulu kune-500mm, kwaye umgama ukusuka esiphelweni sefestile awumelanga ukuba mkhulu kakhulu. Kwi-150mm. Unxibelelwano olumilise u-T kufuneka lube nemingxuma e-150mm kumacala omabini enkxaso ephakathi

5. Ukudibanisa

Xa ukuwelda, nikela ingqalelo kubushushu be-welding 240-250 ° C, uxinzelelo lokondla 0.3-0.35MPA, uxinzelelo lobunzima 0.4-0.6MPA, ixesha elinyibilikayo 20-30 imizuzwana, ixesha lokupholisa imizuzwana engama-25-30. Ukunyamezelana kwentsimbi kufuneka kulawulwe ngaphakathi kwe-2mm Ngaphakathi

6. Coca iikona, faka imitya yerabha

Ukucoca i-Angle yahlulwe yacoca ngesandla kunye nokucoca ngomatshini. Emva kwentsimbi, i-engile inokucocwa emva kwemizuzu engama-30 yokupholisa.

B. Isakhelo, ifeni kunye neglasi yeglasi, faka iintlobo ezahlukeneyo zemigca yerabha ngokweemfuno. Isakhelo, indawo ethe nkqo yerabha yomqhubi;

Ubude bomtya werabha kufuneka bube malunga ne-1% ngaphezulu ukuthintela umtya werabha ekunciphiseni. Akukho kukhululeka, ukugcuma, okanye phakathi emva kokufakwa komphezulu werabha

Ukumisa into

7. Indibano yehardware

Iingcango zeplastikhi zentsimbi ezigqityiweyo kunye neefestile zihlanganisiwe kwisakhelo kunye nefeni ngesixhobo sehardware. Umgaqo wendibano ye-Hardware yile: Amandla aneleyo, indawo echanekileyo, ukuhlangana kwemisebenzi eyahlukeneyo kwaye kulula ukuyibuyisela endaweni, i-hardware kufuneka ilungiswe kuhlobo olufakelweyo oluphuculweyo Kwintsimbi yokufaka, i-Hardware fixing screws kufuneka ifakwe ngokupheleleyo, kunye nendawo yokufaka yehardware kufuneka ngokungqinelana nomgangatho.

8. Ukufakwa kweglasi

Kwindawo apho iglasi kufuneka ifakwe khona, beka ibhloko yeglasi kuqala, ubeke iglasi esisikiweyo kwibhloko, emva koko udlulise iglasi.

9. Ukupakisha kwemveliso kugqityiwe kunye nokuhlolwa komgangatho

Phambi kokuba kwenziwe iingcango kunye neefestile kwaye ziwushiye umzi-mveliso, kufuneka zipakishwe ukuthintela ungcoliseko. Ngaphantsi kwesiseko sokufakwa kwesandi, ukupakishwa kwamacala amabini. Iteyiphu yokupakisha emacala-nye ayiyi kuba ngaphantsi kwamanqaku ama-3 kwaye isithuba asiyi kuba ngaphezu kwe-600 mm. Emva kokupakisha, phawula ubungakanani befestile kwindawo ebonakalayo. Emva kokuba iingcango zeplastiki kunye neefestile zihlanganisiwe, kufuneka kuhlolwe ngokungqongqo umgangatho.

A.Ukuhlolwa kweNkangeleko: Umphezulu wengcango kunye neefestile kufuneka ubengagudileyo, ungabinamabhamu kunye nokuqhekeka, iyunifomu ngombala, kwaye i-welds kufuneka igudile, kwaye akufuneki kubekho mabala acacileyo. Iziphene ezinjengokungcola;

B. Ukuhlolwa kobungakanani bembonakalo: lawula ngokungqongqo umgangatho weengcango kunye neefestile ngaphakathi kokutenxa okuvumelekileyo komgangatho womzi mveliso wesizwe;

C. Imicwe yokutywina ixhotyiswe ngokufanayo ngamanqatha, amalungu adibeneyo, kwaye akukho nto yenzekayo;

D epheleleyo.Umtya wokutywina kufuneka uhlanganiswe ngokuqinileyo, kwaye umsantsa ophakathi kweekona kunye namalungu eempundu akufuneki abe mkhulu kune-1mm, kwaye akufuneki abekho kwicala elinye. Sebenzisa imitya emibini okanye nangaphezulu yokuncamathela;

Ewe. Izixhobo zehardware zifakwe kwindawo echanekileyo, zigqityiwe ngobungakanani, kwaye zafakwa ngokuqinileyo.

Ixesha Post: Aug-23-2021